Paper Cup Fan Die Cutting and Stripping Machine

Product Video

Technical Specification

| Model | FD970*550 |

| Max cutting area | 940mm*520mm |

| Cutting precision | ±0.20mm |

| Paper weight | 120-400g/㎡ |

| Production capacity | 90-140 times/min |

| Air pressure requirement | 0.5Mpa |

| Air pressure consumption | 0.25m³/min |

| Max cutting pressure | 150 T |

| Machine weight | 6T |

| Max paper roll diameter | 1600mm |

| Total power | 20KW |

| Stripping precision | 99% |

| Height of stacking | 18-25mm |

| Suitable paper width | Max 910mm min 600mm |

| Total weight | 8T |

| Dimension | 8000x2500x2000mm |

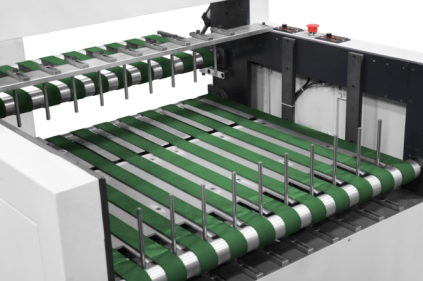

Main Structure

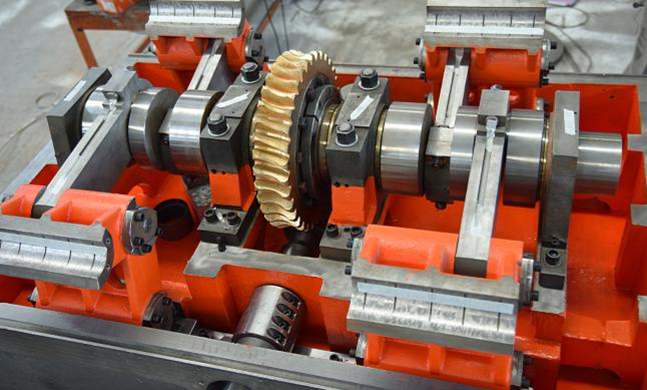

Worm Gear Structure: Perfect worm wheel and worm transmission system ensures the powerful and steady pressure and makes the cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure.

Main base frame, moving frame and top frame are all adopts high strength Ductile Cast Iron QT500-7, which has features of high tensile strength, anti-deformation and anti-fatigable

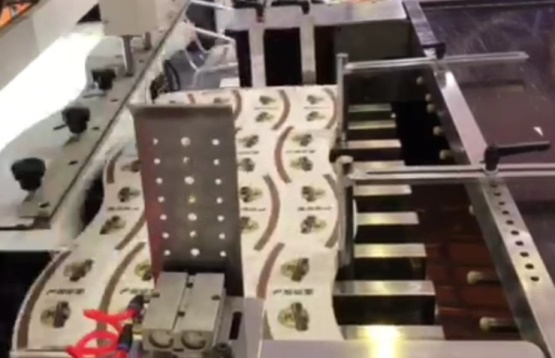

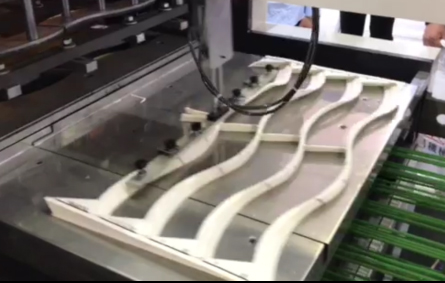

Stripping Detail

The stripping unit is controlled by servo motors and it is found to have reciprocating motion which can synchronize with the roll die cutting machine speed. And the stripping section could be adjustable by manual, the suitable width is between 500-910mm. The pressure of punching reaches 2 tons.

After stripping, the wastage will be taken down and put into the wastebasket automatically, then the paper cup fans will be collected orderly. It reduces much expenses of labor but improve the efficiency.

Exhibitions and Teamwork

FAQ

Q: How to go to your factory?

A: We are located in Wenzhou, Zhejiang Province. To Wenzhou Longwan airport by Air, from Shanghai is about 45mins, from Guangzhou is about 1hr 50mins and from Hongkong is about 2hrs. We will pick up you in the airport.

Q: What’s the payment terms?

A: TT (30% deposit, the balance70% before delivery).

Q: How about the delivery time?

A: 45-60 working days after receiving the deposit

Q: How about the warranty?

A: Spare parts guarantee for one year from the date of installation.

Q:How about the after-sale service?

A:We can Send the technician for installation & training. But the buyer should pay the cost of air tickets and labour.