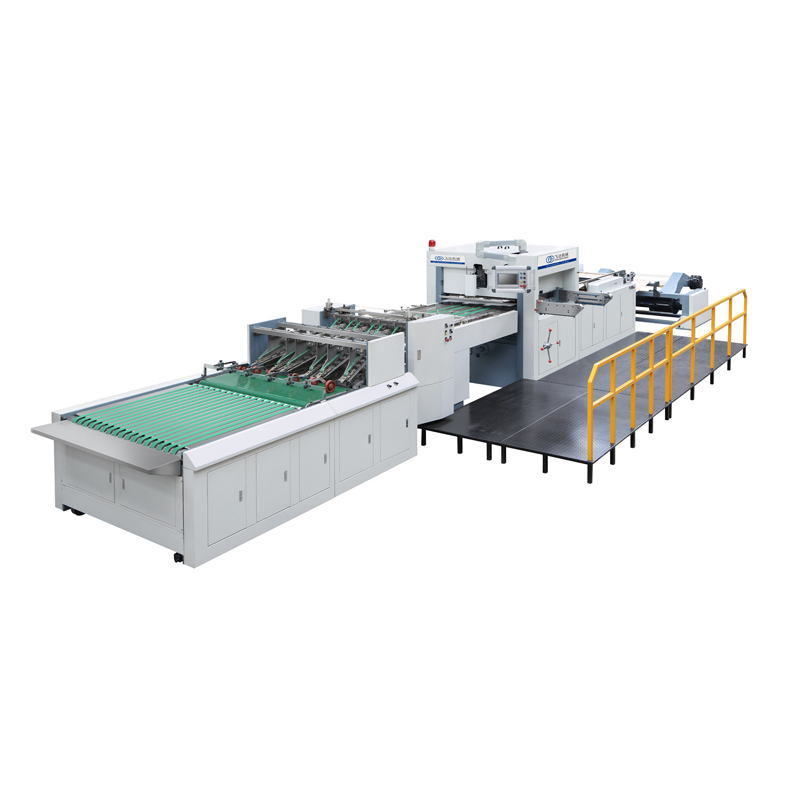

China Beat Coffee Cup Maker Machine Manufacturer – High Speed Paper Cup Forming Machine – FEIDA

China Beat Coffee Cup Maker Machine Manufacturer – High Speed Paper Cup Forming Machine – FEIDA Detail:

Product Video

Specification

| Paper Cup Specification | 4-16oz(100-450ml) (mold exchangeable)

Top: 55-90mm Height: 60-135mm Bottom: 55-70mm |

| Paper Specification | 150-350 GSM single/double PE coated paper or PLA coated paper |

| Production Capacity | 120-150pcs/min |

| Power Source | 380V 50HZ/60HZ 3Phases |

| Average Power | 12KW (Total Power: 18KW) |

| Air Supply Requirement | Air pressure:0.5-0.8Mpa Air out-put:0.4cbm/min |

| Total Weight | 3500KG |

| Package Size | (L*W*H): 2800*1600*1850mm |

Machine Detail

1. The paper cup fans will be sucked down and pushed forward. After the 2 sides of sealing surface are pre-heated, the paper cup body sleeve will be sealed on the horizontal forming mold by Ultrasonic.

2. Direct paper cup bottom punching device controlled by Servo motor which is more accurate and paper-saving.

3. After punching the bottom, the cup molds with paper cup bottom will be transferred to accept the paper cup body sleeve. The sleeve will be turned over up and go through the molds.

4. The molds with sleeve and bottom will be heated twice by the hot air guns. And then the end of the sleeve will be pre-folded inward to get ready for sealing with the paper cup bottom.

5. After the twice hot air gun heating and inward pre-folding, the paper cup bottom will be completely sealed well by the embossing and sealing device. Then the well-bottom-formed paper cups will be transferred to the Second turntable to form the top curling.

6. Before the top curling, the cup top will be moistened by the food grade silicone oil to make the curling top pressure well-distributed to avoid the burst, which will improve the paper cup aesthetic degree.

7. After the oil moistening, the cup top will be curled twice. Compared with once curling, twice curling is more suitable on high speed machine which makes the cup curling more compact and better-looking.

To this step, a cup is done. The cups will be blown to the acrylic pipe to the collection table. Each stack quantity will be counted.

Machine Characteristics

1. Speed: 120-150cups/min

2.This machine adopts intermittent indexing cam mechanism of open type.

3. Gear transmission and vertical axis structure contribute to a reasonable distribution of various functional components.

4. The whole machine uses automatic spray lubrication system, reducing the wear of machine parts, support the machine to work for a long time without interruption.

5. About 13 sensors on 1 machine to monitor the whole cup making process

6. The body of paper cup and the bottom of cup portion bonded by Swiss (Leister brand) heater, ensuring the stability of adhesion

7. Two times curling , first one is rotating curling , second one is heating stereotypes , which improves the forming strength of paper cup, cup mouth beauty and paper cup size stability.

8. PLC and touch screen control is used in cup forming, photoelectric eye is adopted in the entire failure control process.

9. Servo motor paper feeding improves equipment stability, achieves fast steady running, implements automatic fault stop and largely reduces labor cost

Production Efficiency

1. Production output up to 60,000 cups per shift (8 hours)

2. Percentage of pass is higher than 99% under normal production

3. One operator can handle several machines at the same time

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for China Beat Coffee Cup Maker Machine Manufacturer – High Speed Paper Cup Forming Machine – FEIDA , The product will supply to all over the world, such as: Malaysia, Russia, Latvia, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.