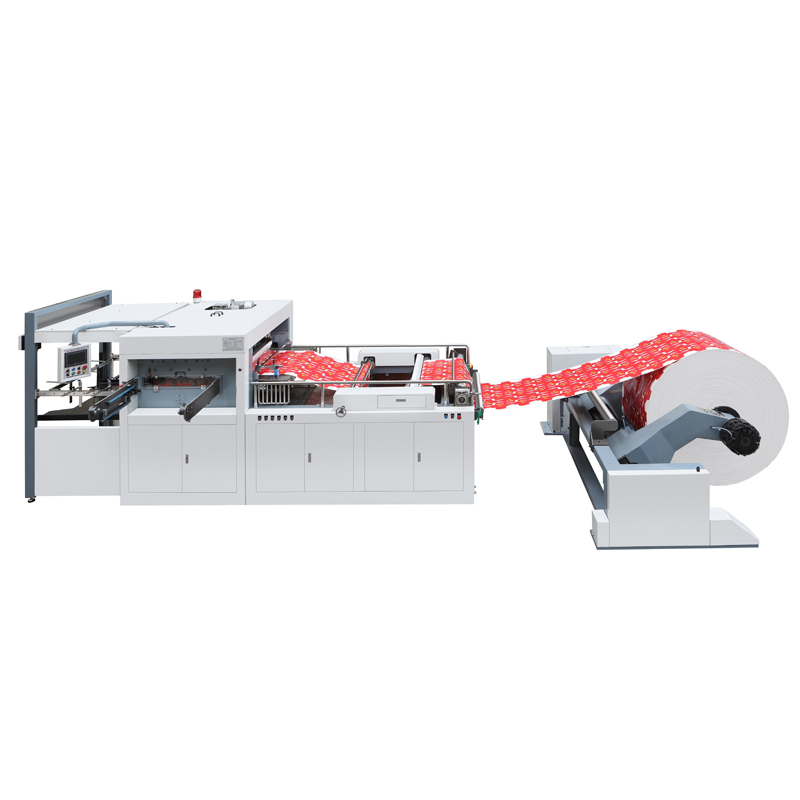

China Beat Die-Cutting Machine Companies – High Pressure Die Cutting Machine ( Embossing ) – FEIDA

China Beat Die-Cutting Machine Companies – High Pressure Die Cutting Machine ( Embossing ) – FEIDA Detail:

Product Video

Technical Specification

| Model | FD970*550 |

| Max cutting area | 950mm*530mm |

| Cutting precision | ±0.20mm |

| Paper weight | 120-600g/㎡ |

| Production capacity | 120-180 times/min |

| Air pressure requirement | 0.5Mpa |

| Air pressure consumption | 0.25m³/min |

| Max cutting pressure | 280 T |

| Machine weight | 7.5T |

| Max paper roll diameter | 1600mm |

| Total power | 12KW |

| Dimension | 4500x2200x1800mm |

Characteristic

1.Worm Gear Structure: Perfect worm wheel and worm transmission system ensures the powerful and steady pressure and makes the cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure.Main base frame, moving frame and top frame are all adopts high strength Ductile Cast Iron QT500-7, which has features of high tensile strength, anti-deformation and anti-fatigable.

2.Lubrication System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, machine will shut down for protection if oil pressure is low. The oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil.

3. The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

Pneumatic clutch brake: through adjust the air pressure to control the driving torque, low noise and high brake performance. The machine will shut down automatically if overload happened, response sensitive and fast.

4. Electrical control pressure: accurate and fast to achieve die-cutting pressure adjustment, The pressure is automatic adjusted through the motor to control the four feet by HMI.It is very convenient and accurate.

5. It can die-cut according to the printed words and figures or simply die-cut without them. The coordination between stepping motor and photoelectric eye which can identify colors assures the perfectly fit of the die-cutting position and figures. Simply set the feed length through the micro-computer controller to die-cut the products without words and figures.

Embossing Samples

Exhibitions and Teamwork

FAQ

Q: How to go to your factory?

A: It is very convenient to take a plane from Shanghai/Beijing/Guangzhou to our city “Wenzhou”.

Q: What’s the payment terms?

A: TT (30% deposit, the balance70% before delivery).

Q: How about the delivery time?

A: 45-60 working days after receiving the deposit

Q: How about the warranty?

A: Spare parts guarantee for one year from the date of installation.

Q:How about the after-sale service?

A:We can Send the technician for installation & training. But the buyer should pay the cost of air tickets and labour.

Product detail pictures:

Related Product Guide:

"Quality very first, Honesty as base, Sincere assistance and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for China Beat Die-Cutting Machine Companies – High Pressure Die Cutting Machine ( Embossing ) – FEIDA , The product will supply to all over the world, such as: Hamburg, Oman, India, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!