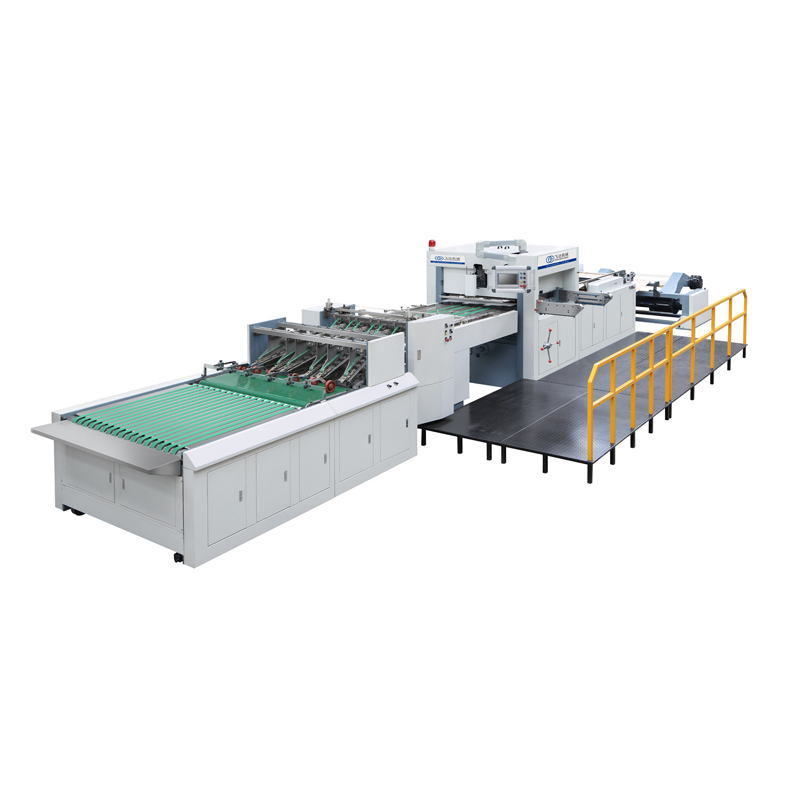

China Beat Paper Cup Die Cutting Machine Manufacturer – Roll Die Cutting With Printing In Line Machine – FEIDA

China Beat Paper Cup Die Cutting Machine Manufacturer – Roll Die Cutting With Printing In Line Machine – FEIDA Detail:

Product Video

Machine Detail

Die cutting Technical Specification

| <p “>Model | FD-970×550 |

| Max cutting area | 940mmx510mm |

| Cutting precision | ±0.20mm |

| Paper gram weight | 120-400g/㎡ |

| Production capacity | 90-140times/min |

| Air pressure requirement | 0.5Mpa |

| Air pressure consumption | 0.25m³/min |

| Max cutting pressure | 150T |

| Weight | 5.5T |

| Max roller diameter | 1600mm |

| Total power | 12KW |

| Dimension | 4500x2200x1800mm |

Electric Configuration

| Stepper motor | Schneider |

| Pressure adjusting motor | Taiwan |

| Servo driver | Schneider |

| Color Sensor | Sick(Germany) |

| PLC | Schneider |

| Frequency converter | Schneider |

| All other electrical parts | Siemens |

| Photoelectric switch | Leuze |

| Main air cylinder | AirTAC (Taiwan) |

| Solenoid valve and other parts | AirTAC (Taiwan) |

| Pneumatic clutch | China |

| Main bearings | Germany |

Printing Part

Characteristics:

1) Adopt the anilox roller to spread ink.

2) Unwinding tension is controlled by automatic tension controller from Japan Mitsubishi.

3) Each printing unit adopt 360°for registration.

4) Each printing unit have one IR dryer

5) The rubber roller can break away automatically while parking, and run at a low speed in order to avoid ink being dry.

6) The main motor is adopted the import stepless regulation of frequency conversion.

7) Unwinding, web guiding, printing, IR drying and punching can be finished in one process

Main Technical Variables:

| Web width | 960mm |

| Print width | 950mm |

| Unwind Diameter max | 1200mm |

| Press Speed max(Production speed depending on process, job etc.) | 80m/min |

| Gear Pitch | 1/8” (3.175mm) |

| Flexo Print Units (IR dryer): | 2 |

| Min.Max repeat Print Cylinder | 10” – 22.5” |

| Web Guiding: number | 1 |

| Overprint precision | ±0.15mm |

| Machine weight | 5000kg |

Note:

| Voltage | 3 phase 380V, 50HZPlease kindly inform us if different |

| Diameter of air shafts | 76mmPlease kindly inform us if different |

| Diameter of printing plate | 1.7mmPlease kindly inform us if different |

| Diameter of plate mounting tape | 0.38mmPlease kindly inform us if different |

| The size of printing cylinder and ceramic anilox roller also need to inform us. | |

Configure:

| Ceramic anilox roller | 6 pcs, lines from 200-1000 choose by buyer | Cuntian, Shanghai |

| Printing roller | 6pieces * 1sets = 6 pcs,(buyer offers dimension) | |

| Unwinding tension controller | Japanese Mitsubishi | |

| Magnetic powder brake | Chinese brand | |

| Temperature controller | XMTG-6501 | Yuyao , Zhejiang |

| Main motor | Wannan , Anhui | |

| Converter | YASKAWA, Japan | |

| Button | Schneider , France | |

| All low-tension electrical | Schneider , France | |

| Web guiding | ZXTEC, Ruian |

Exhibitions and Teamwork

FAQ

Q: How to go to your factory?

A: It is very convenient to take a plane from Shanghai/Beijing/Guangzhou to our city “Wenzhou”.

Q: What’s the payment terms?

A: TT (30% deposit, the balance70% before delivery).

Q: How about the delivery time?

A: 45-60 working days after receiving the deposit

Q: How about the warranty?

A: Spare parts guarantee for one year from the date of installation.

Q:How about the after-sale service?

A:We can Send the technician for installation & training. But the buyer should pay the cost of air tickets and labour.

Product detail pictures:

Related Product Guide:

Our business puts emphasis on the administration, the introduction of talented personnel, as well as the construction of team building, trying hard to further improve the standard and liability consciousness of staff members customers. Our enterprise successfully attained IS9001 Certification and European CE Certification of China Beat Paper Cup Die Cutting Machine Manufacturer – Roll Die Cutting With Printing In Line Machine – FEIDA , The product will supply to all over the world, such as: Slovak Republic, Rome, Uganda, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.